Essential Fuel Tanker Parts: A Comprehensive Guide

In the transportation industry, fuel tankers play a crucial role. They are specially designed to transport fuels safely and efficiently. Understanding the various components that make up fuel tankers is essential for operators, maintenance personnel, and anyone involved in the transport of liquids. In this article, we will explore the vital fuel tanker parts, their functions, maintenance, and tips for ensuring longevity and safety.

1. Understanding Fuel Tankers

Before diving into the specific parts of fuel tankers, it is important to understand the type of vehicles we are discussing. Fuel tankers are specially designed trucks or trailers equipped with tanks to transport liquid fuels. They vary in size and design, often categorized by the type of fuel they transport, such as gasoline, diesel, or liquid propane.

1.1 Types of Fuel Tankers

Fuel tankers can be classified into two main types:

- Rigid Fuel Tankers: These vehicles consist of a chassis and a tank that is mounted directly to the vehicle. They are often used for urban deliveries and shorter distances.

- Articulated Fuel Tankers: These consist of a separate trailer attached to a tractor unit. They are commonly used for long-distance transport due to their larger capacity and stability.

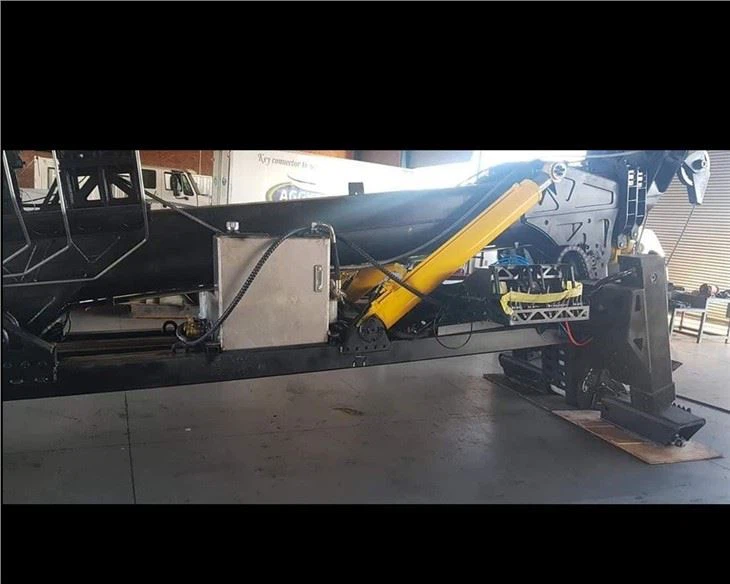

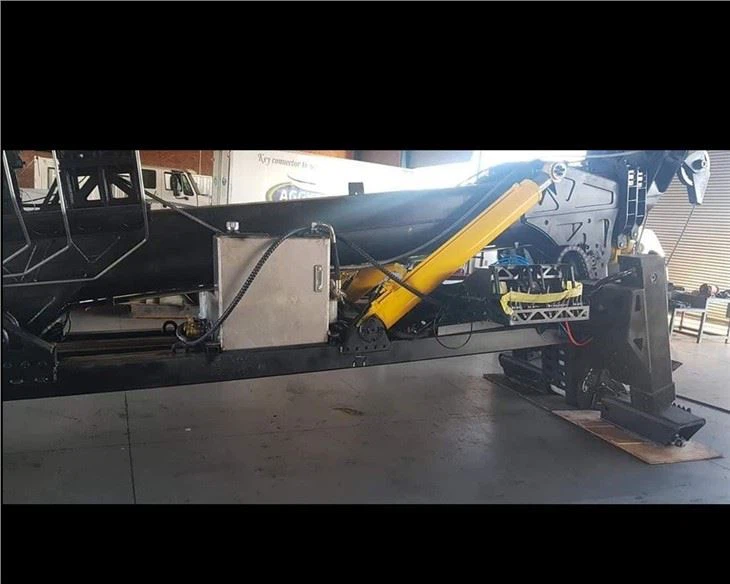

2. Basic Components of Fuel Tankers

Each fuel tanker is made up of several critical parts that work together to ensure safe and efficient transport. Here are some of the primary components:

2.1 Tank

The tank is the most significant component, designed to hold the fuel. It is usually made from durable materials like steel or aluminum, ensuring it can withstand high pressures and prevent leaks. Tanks often come in different shapes, such as cylindrical or elliptical, and can have multiple compartments for carrying different fuel types.

2.1.1 Safety Features of Tanks

Modern fuel tanks are equipped with numerous safety features:

- Venting Systems: Essential for preventing pressure build-up.

- Overfill Protection: Prevents spills during loading.

- Internal Coatings: Prevent corrosion and enhance durability.

2.2 Pumping Systems

Pumping systems are vital for transferring fuel from the tanker to storage facilities or other vehicles. These systems include:

- Fuel Pump: Moves the fuel from the tank to the desired location.

- Hoses and Nozzles: Facilitate the dispensing process.

- Metering Devices: Ensure accurate quantities are delivered.

2.3 Valves

Valves control the flow of fuel within the tanker. They are crucial for stopping the fuel flow during loading and unloading processes. Common types include:

- Shut-off Valves: Used to stop fuel flow quickly.

- Check Valves: Prevent backflow of fuel.

- Drain Valves: Facilitate the complete emptying of tanks.

2.4 Hose Reels and Hoses

Hose reels are essential for storing fuel hoses when not in use. They provide a practical solution for managing the hoses while also ensuring they remain in good condition. The hoses themselves must be durable, flexible, and capable of handling the type of fuel carried.

2.5 Gauges and Sensors

Gauges and sensors provide critical information regarding the fuel levels, temperature, and pressure within the tank. Examples include:

- Level Gauges: Indicate the amount of fuel in the tank.

- Pressure Sensors: Monitor the pressure within the tank.

- Temperature Sensors: Help in maintaining fuel quality.

3. Maintenance of Fuel Tanker Parts

Regular maintenance of fuel tanker parts is crucial to ensure safety and functionality. Here are some practical tips for maintaining your fuel tanker:

3.1 Routine Inspections

Scheduled inspections help identify potential issues before they become serious. Key points to check include:

- Visual inspections for leaks and damage.

- Testing valves for proper operation.

- Checking hoses for wear and tear.

3.2 Cleaning Procedures

Fuel tanks should be cleaned regularly to prevent contamination. Common cleaning practices include:

- Draining residual fuels before cleaning.

- Using specialized cleaning solutions to avoid chemical reactions.

- Ensuring thorough rinsing to remove all cleaning agents.

3.3 Professional Servicing

It is advisable to have professional servicing done periodically. This includes testing and calibrating pumps and meters, as well as inspecting internal tank conditions. Servicing can extend the life of your fuel tanker significantly.

4. Safety Considerations in Fuel Tankers

Given the hazardous nature of fuels, safety cannot be overlooked in the operation and maintenance of fuel tankers. Here are essential safety tips:

4.1 Hazardous Materials Training

All personnel operating or handling fuel tankers should undergo relevant training. Knowledge about hazardous materials improves safety in loading, unloading, and emergency situations.

4.2 Proper Equipment Usage

Proper usage of all equipment, especially pumps and hoses, is crucial in preventing accidents. Operators must be trained to handle equipment correctly and understand the procedures involved.

4.3 Emergency Protocols

Establishing clear emergency protocols is vital for dealing with leaks or spills. Staff should know evacuation procedures, how to use fire extinguishers, and how to report incidents effectively.

5. Key Suppliers of Fuel Tanker Parts

Choosing reliable suppliers for fuel tanker parts is essential for ensuring quality and safety. Here are some well-known suppliers:

| Supplier Name | Specializes In | Contact Information |

|——————–|————————-|——————————-|

| Tanker Parts Co. | Tank manufacturing | www.tankerparts.com |

| Fuel Systems Inc. | Pumping systems | www.fuelsystems.com |

| Safety Tankers LLC | Safety equipment | www.safetytankers.com |

5.1 Choosing the Right Supplier

Consider the following when selecting a supplier:

- Reputation in the industry.

- Quality certifications.

- Customer support and warranty options.

6. Innovations in Fuel Tanker Technology

The fuel transport industry is continuously evolving. Here are current trends and innovations:

6.1 Smart Tanker Technology

Modern fuel tankers are incorporated with IoT devices, allowing for real-time tracking of fuel levels, and monitoring of tank conditions. This technology enhances safety and helps prevent overfilling or spills.

6.2 Lightweight Materials

Innovations in materials like carbon fiber and advanced alloys lead to lighter tanker designs, improving fuel efficiency during transportation.

6.3 Environmental Compliance

New regulations are enforcing greener practices in fuel transportation. Innovations focused on reducing emissions and leaks are becoming standard in new tanker designs.

7. Practical Examples of Fuel Tanker Parts Issues

Real-world scenarios often highlight the importance of maintaining fuel tanker parts.

7.1 Leak Detection

Consider a situation where a fuel tanker experiences a leak due to a faulty valve. Regular inspections could have identified the issue early, preventing a spill and its consequences.

7.2 Pump Failures

In another case, a tanker is unable to unload fuel due to a malfunctioning pump. Maintenance checks would have allowed for timely repairs, reducing downtime and potential losses.

8. FAQs about Fuel Tanker Parts

8.1 What are the most critical components of a fuel tanker?

The most critical components are the tank itself, pumping systems, valves, hoses, and gauges. Each part plays a vital role in safe fuel transport.

8.2 How often should fuel tankers be serviced?

Fuel tankers should undergo routine inspections every six months, with preventive maintenance and servicing done annually or as needed.

8.3 What safety features should be included in a fuel tanker?

Modern fuel tankers should have overfill protection, venting systems, spill kits, and proper labels indicating hazardous materials.

8.4 How can I extend the life of my fuel tanker’s parts?

Regular maintenance, proper cleaning, and timely repairs are essential for extending the life of fuel tanker parts.

8.5 Are there specific training requirements for operating fuel tankers?

Yes, operators should receive training in hazardous materials handling, emergency protocols, and equipment operation to ensure safety during operations.

8.6 What are the environmental regulations for fuel transport?

Regulations vary by region but generally focus on spill prevention, emissions controls, and proper handling of hazardous materials to minimize environmental impact.