Mobile Compactor Garbage Station

16CBM Garbage Container

3.5CBM Hopper

120L/240L Bin Lifter

PLC Control Panel

Hydraulic Lock

|

|

|

|

Description

DESCRIPTION

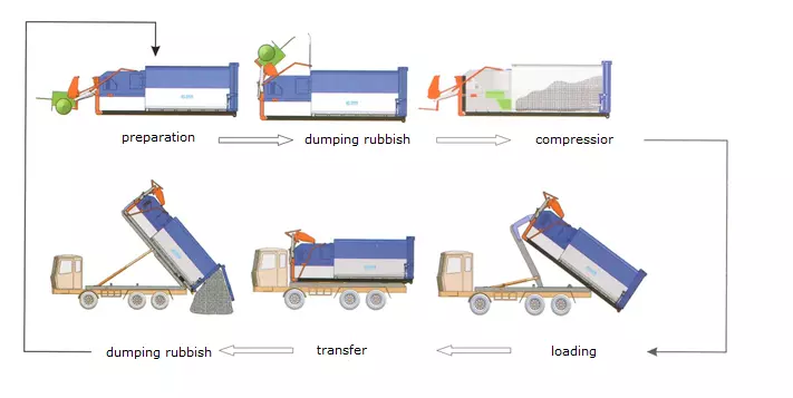

The Mobile Compactors Station are closed systems to compact and store waste which can be placed at any location and does not require ground fixing or housing in a special building. These compactors have high volumetric efficiency and compaction ratio, rubber seals, and power pack with frequency control design. These features deliver many benefits, including faster compaction; no leakage; better hygiene; higher payload; lower energy consumption; lower noise, and, easier maintenance.

- CSCTRUCK’s range of bin lifters enables customers to safely and efficiently empty their waste containers. All of our systems can be individually tailored to your requirements. CSCTRUCK container tipping mechanism, it is possible to lift and empty almost any type of wheelie bin or waste box into a waste compactor or a roll-on/off container.

- These units can vary from a fixed, integrated unit of a compactor or a mobile bin lifter to a floor-bolted unit which is designed to tip at a specific height to feed a larger container or hopper. The units are available with various power options, either fully hydraulic, hydraulic, and chain, or electric chain driven.

- Our mobile wheelie bin lifting equipment is perfect when lifting 80/120/240lit. EN840 wheelie bins, or larger 660/770/1100lit. EN840 wheelie bins into open-top containers or portable and static compactors. These units are mobile on two fixed and two swivel braked castors and can be easily maneuvered from location to location.

- For directly loading large quantities of light and bulky waste into portable waste compactors, we supply fixed, integrated loading shovels with loading volumes up to 3.5m³.

SPECIFICATION

|

ITEM MODEL |

GCS16 |

||

|

Size |

Length (mm) |

Bin Lifter Down |

8600 |

|

Bin Lifter Up |

6200 |

||

|

Width (mm) |

2480 |

||

|

Height (mm) |

2650 |

||

|

Volume(CBM) |

18 |

||

|

Compression Body |

Length (mm) |

1450 |

|

|

Width (mm) |

1980 |

||

|

Height (mm) |

480 |

||

|

Volume (m3) |

1.37 |

||

|

Weight |

Curb Weight(t) |

≥5 |

|

|

Max Pay loading Weight(t) |

10.5 |

||

|

|

Compaction Ability(m3/h) |

≥82 |

|

|

Compaction Density(kg/m3) |

≥700 |

||

|

Compression Stroke (mm) |

1000 |

||

|

Cycle Time (S) |

35-45 |

||

|

Hopper Capacity (m3) |

2.5 |

||

|

Hydraulic Pressure(MPa) |

16 |

||

|

Flow Rate(l/min) |

17 |

||

|

Ejector Plate Push Ability(N) |

≥250000 |

||

|

Voltage(VAC) |

380 |

||

|

Power(KW) |

5.5-7.5 |

||

|

Operation Ability(t/h) |

≥9.5 |

||

|

Lifting Cycle Time (S) |

30—40(adjustable) |

||

|

Hopper Width (mm) |

1960 |

||

|

Max. Working Pressure(MPa) |

21 |

||

|

Noise(dB(A)) |

≤70 |

||

|

Lifting Cylinder Push Ability (KN) |

≥10000 |

||

|

Voltage(VDC) |

24 |

||

|

Ambient Temperature(℃) |

-15/17—40 |

||

|

Rear Door |

Pressure(MPa) |

16 |

|

|

Flow Rate(l/min) |

4 |

||

|

Power Interface |

Hook Lift Truck Power Supply |

||

|

Power(KW) |

0.8 |

||

|

Voltage(VDC) |

24 |

||

|

Close Time (S) |

40-75 |

||

|

Control System |

Motor |

5.5-7.5Kw Siemens Motor |

|

|

Hydraulic Pump |

High-pressure gear pump imported from Italy |

||

|

Control Valve Group |

Imported from Italy ATOS electromagnetic reversing valve, hydraulic lock, overflow valve, etc. |

||

|

Hydraulic System Piping |

1. Adopt international general DIN24° standard 2. The hard tube adopts a precision seamless bright tube (the hard tube and the pipe joint adopt a non-welded connection) |

||

|

ECU |

1. PLC adopts Siemens series programmable controller 2. The external interface adopts touch screen 3. Relays, travel switches, etc. all use Schneider Electric components 4. The pressure sensor adopts components customized by Honghui Technology from Germany |

||

|

Air Cooling Device |

The hydraulic oil tank is equipped with a high-efficiency and low-noise air cooler to ensure the normal operation of the system at the set temperature. |

||

|

Wireless Control |

Imported remote control device, which can be operated effectively at any angle within 30 meters (optional) |

||